CP-E customizes the new Ford Bronco at breakneck speed with Artec 3D scanning

Challenge: Finding a faster, more precise way of digitizing car undercarriages, so they can be customized to meet rising demand for design and performance enhancements.

Solution: Artec Leo, Artec Studio, Geomagic Design X

Result: Ditching low-resolution scanning and probe measurement for digitization with Artec Leo has made CP-E’s data capture process up to eight times faster. Upgrading has also enabled its team to rapidly develop custom exhausts for Ford’s beastly new V6 engine Bronco SUV.

Why Artec 3D?: In tandem, Artec Leo’s 35 million pt/s scan speed and Artec Studio AI accelerate reverse engineering and inspection. With a built-in display and wireless functionality, Leo has also freed the firm from a reliance on cumbersome PCs and cables – streamlining its workflow and allowing its team to spend more time on value-adding tasks.

CP-E’s Anthony Messina 3D scanning the underside of a vehicle with Artec Leo. Photo courtesy of CP-E.

In the modern automotive industry, reverse engineering continues to address all sorts of urgent design and manufacturing needs. Need to unpick a design concept, modify an existing part, or source a discontinued spare? Reverse engineering is the perfect place to start.

One of many now monetizing this process of extracting design information, US-based Custom Performance Engineering (CP-E), utilizes captured data to help clients boost vehicle power and performance. Over the years, it has developed custom parts for numerous cars by huge brands such as BMW, Audi, and Ford, but until recently, it had found doing so very time-consuming.

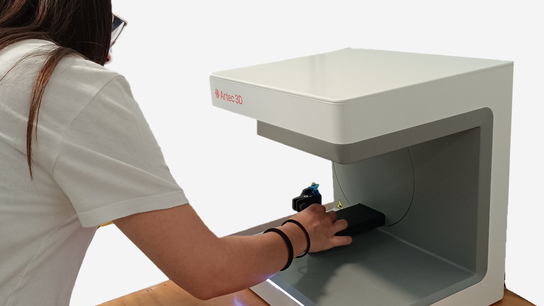

CP-E’s previous workflow saw it measure car underbodies via a robotic arm, mounted with a low-resolution scanner and coordinate measuring machine (CMM) probe. Although this was faster than the manual measurement that still prevails in much of the industry, speed remained a bottleneck in its workflow, and data capture proved patchy at best.

Facing tight deadlines, the CP-E team knew they needed to change course, and they’ve since found the structured-light 3D scanner Artec Leo perfect for tackling their customization challenges.

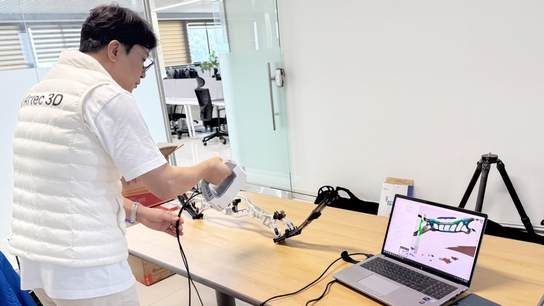

Artec Leo’s built-in display makes complete object data capture quick and easy. Photo courtesy of CP-E.

Switching to structured light

Describing the firm’s early robot arm-mounted scanning efforts as “a complete disaster,” CP-E CEO & President Anthony Messina set out to not make the same mistake twice. Initially, he reached out to Artec Ambassador Digitize Designs to get a demo of a wired 3D scanner.

However, when they arrived and showcased Artec Leo, he was immediately sold on the speed and self-contained nature of the device, which blew away the competition on-show. Already, Messina says this throughput along with the device’s accuracy of up to 0.1 mm, has made it an indispensable part of CP-E’s vehicle exhaust modification business.

“It’s kind of mind-blowing how much faster it is,” said Messina. “It depends on the part. If I’m scanning a simple part like an exhaust pipe, it’s two times as fast, but if we’re talking a whole car, the gains are a lot more significant. Data capture previously took one or two hours, now with Leo, I’m probably only spending 15-30 minutes.”

“With our robotic arm, we’d get a rough idea of where things were, but Artec Leo gives us the whole picture – we know which contours we can use and which to stay away from.”

Messina capturing an exhaust pipe in-situ with Artec Leo. Photo courtesy of CP-E.

In the past, CP-E would have exported scans to a third-party software for reverse engineering or quality inspection tasks, but it now performs many of these in Artec Studio. In fact, the program’s editing tools are now so advanced, he can use them to process simple parts in their entirety, only exporting to Geomagic Design X to find cylindrical exhausts’ ‘center lines.’

“Even with the complicated stuff, I’ll do all the alignment (putting multiple meshes together) in Artec Studio as it’s much faster than other platforms,” explained Messina. “There’s times I think ‘Oh shoot! I didn’t scan this.’ I can just quickly go in, scan it, process, and align it. It only goes into Geomagic Design X if we’re measuring an exhaust for bending.”

Bronco modding and beyond

One of the latest vehicles to get the CP-E customization treatment is the 2023 Ford Bronco. So new it only landed in Europe recently, the SUV comes with a 300 horsepower turbocharged engine that makes it capable of accelerating from 0-100 km/h in just 6.7 seconds.

While it’s clearly no slouch, CP-E has now been charged with modifying the car’s exhaust, to improve performance while meeting demand for different variations of the model.

“On the new Bronco, we’re doing a lot of exhaust work,” said Messina. “There are many different options: you might have an exhaust that is just a single exit at the rear, or a dual exit. Some even want an exhaust that exits in front of the tire. In order to make these changes work, you’ll need a complete picture – that’s why we’re using 3D scanning.”

Artec Leo digitizing a detached exhaust pipe. Photo courtesy of CP-E.

Once Leo has helped meet demand for exhaust-modified Broncos, Messina says CP-E “would like to do more on the quality assurance side of things,” and it’s also eyeing an expansion into the manufacturing space. In both areas, the firm sees 3D scanning as key to its prospects.

“We’re trying to do more manufacturing and get longer-term contracts where we do hundreds of these jobs a month,” concluded Messina. “Of course, we know automotive has good and bad periods, so we’re just making sure that we produce models that match design drawings so we’re ready – ultimately that’s where I see the future of 3D scanning.”

Scanners behind the story

Try out the world's leading handheld 3D scanners.