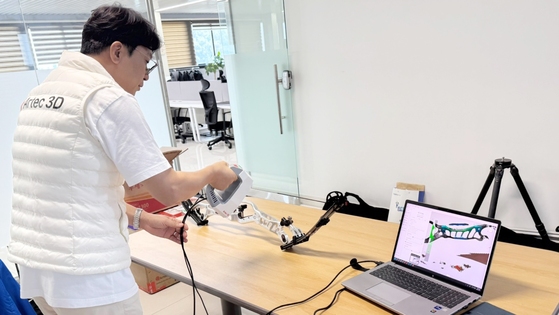

Originally from London, Paul Hanaphy is a journalist turned marketing content writer at Artec 3D. Since going full-time as a journalist five years ago, Paul has reported on everything from local news to stories with national and even international dimensions. Following a stint at a regional newspaper, Paul turned a long-standing interest in advanced technologies into a career, by joining an industry publication and writing articles for 3D Printing Industry.

While putting together news, features, and interview pieces, Paul became better acquainted with the disruptive potential of 3D printing and 3D scanning. During his time at the publication, Paul also covered and spoke at industry events like Formnext, Rapid+TCT, and IMTS, quickly becoming an authoritative voice for those working in the sector.

Paul has a keen interest in automotive and aerospace – and over the years, this has been reflected in his work. After his graduation from Kingston University with a Master’s Degree in journalism, Paul went on to cover racing series like NASCAR and Formula 1, as well as popular British showcases such as the Goodwood Festival of Speed and Farnborough Airshow.

Aiming to get ever-closer access to such technological innovation, Paul left the British Isles in early 2023, to begin a new European adventure at Artec 3D. As part of the Artec team, he now curates content for those seeking to better understand how 3D scanning works, where it’s beginning to be applied, and how it continues to break boundaries across industries.

When he’s not writing about 3D scanning, Paul is likely playing football, cheering at a racetrack, or clutching a dictionary while trying to order coffee in another language. Want to stay up-to-date with Paul’s latest posts on the 3D industry? Follow his Linkedin page here.