Artec 3D scanners for reverse engineering

Companies have reported saving up to 85% in time and cost just by incorporating our 3D scanners into their reverse engineering workflows.

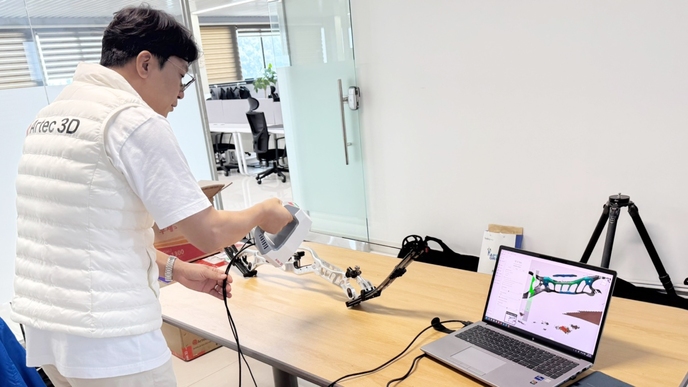

3D scanning for reverse engineering

To be able to digitally reproduce components, or to confidently determine design intent, the instruments you use have to be unquestionably accurate. This makes professional 3D scanners a crucial element in the reverse engineering toolbox, whether for product improvement, reconstruction, design augmentation, or a range of other use cases.

Artec 3D scanners and software are designed with a focus on accuracy, ease of use, and speed in mind. The software is intuitive, the scanners require minimal training, and you can choose whether to seamlessly integrate these 3D scanning solutions into your existing workflow or use them independently.

Benefits

An Artec scanner takes one second to capture up to 35 million points. A CMM needs hours to capture a few hundred.

Precise, metrology-grade 3D scans at up to 2 microns’ accuracy.

Artec scanners are designed to be intuitive, versatile, and easy to use. You’ll be confidently scanning in under 2 hours!

Just by using Artec scanners, an international manufacturer and distributor of construction machine spare parts saves 85 percent in time and cost.

Applications

HD meshes for CAD workflows

Confidently and easily capture data from existing parts with the assurance of ultra-high precision and accuracy.

Rapid prototyping

With tools that seamlessly integrate into your existing workflow, you can quickly and easily prototype, test, and get insightful feedback on design solutions.

Retrofitting

Redesigning parts that are no longer in production has never been easier, with none of the errors, inconsistencies, and time demands that come with taking measurements manually.

Aftermarket parts production

With reliable 3D scan datasets, paired with Artec Studio’s versatility, you have the ability to develop high-quality aftermarket parts.

Additive manufacturing

You can take advantage of the flexibility that 3D printing brings to quickly actualize and test reverse-engineered designs.

Success story

A leading developer of high-performance chassis saves days of work by using Artec Eva, Artec Studio, and Geomagic Design X to engineer custom solutions for racing.

reduction in time spent capturing and processing scans.

“Eva has been such a game-changer. Now I’ll take a bunch of parts and scan them in before lunch. By the end of the day, we’ve done all our analysis, everything is on schedule to create the final design.”

In the media

More on 3D scanning for reverse engineering

All reverse engineering case studies, 3D models, and videos in one place

Artec Spider II

Artec 3D hardware

Explore a range of fast, ultra-high-precision, and robust scanning solutions that have captured everything from a cargo ship to a SIM card tray. With Artec’s scanners, tiny objects with intricate surfaces, or huge industrial components in difficult locations are not an issue.

User-friendly portable laser 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Built for industrial metrology, this lightweight, robust laser handheld scanner captures tricky surfaces with metrological accuracy and repeatability.

Built for scanning in advanced resolution and perfect color, this target-free 3D industrial scanner captures complex geometry and sharp edges.

Powerful long-range laser 3D scanner for precise capture of massive objects and scenes with remarkable speed and high accuracy.

Our bestselling structured-light 3D scanner. Fast, versatile, and accurate.

A metrology-grade 5-micron accuracy desktop 3D scanner and automated, one-click solution.

Photogrammetry kit with 2-micron accuracy, metrology-grade precision, and high volumetric accuracy for inspection, reverse engineering, and other industrial measurement applications.

What’s the next step?

Success stories

Learn all about how teams around the world leverage the power of our scanners to optimize their reverse engineering processes and make best use of their resources.

An industry-leading custom cab enclosure maker can now speed up their reverse engineering workflow to meet deadlines and keep up with rising levels of market demand.

“We were amazed at how fast and painlessly Leo scanned everything, compared to what we were used to in the past with our CMM. Because we design our products around scanned vehicle data, for us this is a massive leap forward in our design-to-build workflow.”

Using Artec Leo to digitize the untextured, organic surfaces of a vintage aircraft with sufficient precision to develop a digital copy that can be used to create functional spares.

“Artec Leo was absolutely the animal for this because of its wider field of view and maneuverability. It would’ve been quite a pain to get inside enclosed spaces or drag a laptop into our setup. The scan was also noise-free and the incredible flexibility of Leo was very cool to see.”

Slashing weeks off reverse engineering farm equipment with Artec Eva

“Eva has literally saved us days if not weeks of work, and that’s no exaggeration. Previously we were spending all that time creating prototypes to test, then that many more hours on alterations to reach the level of perfect, compared to now achieving perfection the first time, and every time, with Eva.”

A Dutch designer and builder of high-speed boats uses Artec Ray to create precise 3D models for reverse engineering, facilitating professional boat construction, and ensuring accuracy.

“Usually such a task is accomplished by refitting and trimming many parts to get everything in place for the hulls created from the molds. So the scanning significantly decreased the need for human labor, with many tasks made in CAD software with submillimeter accuracy even before the hulls were produced.”

Reverse engineering huge machine parts in difficult locations with Artec Eva and Geomagic Design X

“Artec Eva was the suitable scanner for this job as the parts were very big and the accuracy required was in the range of Artec Eva’s accuracy. The scanning was pretty fast and easy considering that those were huge parts, around 3 meters…No other scanner can measure such big parts this accurately and fast.”

Using Artec 3D scanning technology to keep Dutch Royal Navy ships seaworthy

“We are now able to work a lot faster and more accurately. Because we now have a complete 3D model, we have all the correct dimensions of every object. It results in a far more efficient way of working and it is faster, so we save a lot of money in these projects.”

Your best work deserves only the best tech

In reverse engineering, 3D scanning demands are diverse, but the need for accuracy is always high. Artec scanners deliver consistent performance across different usage scenarios.

Which 3D scanner will work best for you?

The Artec line-up offers a solution for everyone, from aerospace engineers working with very large objects to R&D teams working with miniature parts.

User-friendly portable laser 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Built for industrial metrology, this lightweight, robust laser handheld scanner captures tricky surfaces with metrological accuracy and repeatability.

Built for scanning in advanced resolution and perfect color, this target-free 3D industrial scanner captures complex geometry and sharp edges.

Powerful long-range laser 3D scanner for precise capture of massive objects and scenes with remarkable speed and high accuracy.

Our bestselling structured-light 3D scanner. Fast, versatile, and accurate.

A metrology-grade 5-micron accuracy desktop 3D scanner and automated, one-click solution.

Photogrammetry kit with 2-micron accuracy, metrology-grade precision, and high volumetric accuracy for inspection, reverse engineering, and other industrial measurement applications.

Software that lets you be at your best

With such powerful hardware tools at your disposal, it is important that you pair them with similarly capable software. Artec Studio offers a whole range of capabilities that bring the best not just out of your scanner, but you and your team too.

Artec Cloud

Scan an object in one location, reverse engineer it in another, with distributed team members collaborating in real time at every stage.

Also accessible to you

Reverse engineering scanner + software bundles

Everything you need for reverse engineering. Maximize on value by opting for a software and scanner bundle that gives a Geomagic Design X license and one or more Artec Studio licenses.

Flawless 3D scans for CAD modeling

3D scan data that makes the CAD modeling process that much smoother. Here are some of the models from our industry-leading 3D scanners.