Ensuring maritime assets stay shipshape for longer with Artec Leo

Challenge: Naval service provider USP Maritime needed CAD data to carry out repair and refit jobs, both in remote locations and cases where original designs are no longer available.

Solution: Artec Leo, Artec Studio, Autodesk Inventor

Result: Highly detailed vessel component and dockyard machinery models that can be used to accelerate the planning and execution of maritime inspection, retrofit, and restoration.

Why Artec 3D?: Retiring its traditional wired, target-based 3D scanner has revolutionized USP Maritime’s workflow. With a built-in battery and display, as well as advanced geometry and texture tracking, Leo can accurately capture large builds and locations in minutes.

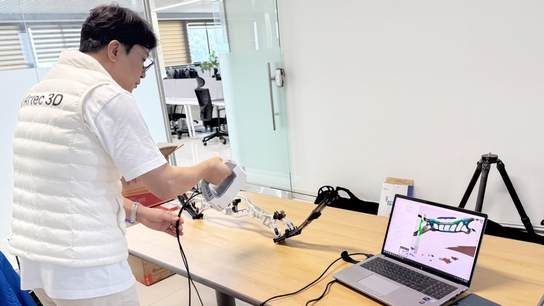

A containerized build being digitized with Artec Leo by a USP Maritime engineer.

Humanity may have long established a presence at sea, but nature can be brutal, and even the toughest vessels to sail the world’s oceans need regular maintenance to stay afloat.

This could simply be a case of waxing, washing, painting, changing oil, or engine repairs, but heavier-duty vessels tend to have more urgent needs. To identify and tackle these as quickly as possible, they’re often subjected to part stability, resistance, and performance analyses.

However, inspecting such assets without missing warning signs is easier said than done. While you could measure entire vessels using a tape, measuring laser, and reference photos, this is labor-intensive and time-consuming in a way that keeps would-be sailors on dry land.

This is where USP Maritime comes in. Through its maritime design consultancy services, the firm generates the geometry data needed for refit, repair, and analysis. Initially, its team digitized data collection using long-range LiDAR and target 3D scanning – with relative success.

But they soon encountered the pitfalls of traditional 3D scanning (relying on targets and a PC, for example). USP Maritime CTO Chris Parke says full-scene capture also yielded “monsters of scans that were very difficult to work with.” His first handheld was apparently even more of a “pain in the a***e,” as it required him to “tilt a laptop in one hand and scan with the other.”

The ultra-flexible Artec Leo allows for data capture in the tightest of confined spaces.

These issues led his firm to plot a new course for maintenance, repair, and overhaul (MRO): using Artec Leo instead. Excited by the prospect of rapid, wireless 3D scanning, USP Maritime Commercial Director James Dryden reached out to Artec Gold-certified partner Patrick Thorn & Co, who delivered in-depth demos of the device’s capture capabilities online and in-person.

Convinced of Leo’s ability to digitize large builds at pace, USP Maritime acquired the scanner and lined up a crane digitization project for the day after it arrived. To get its team up to speed, Patrick Thorn issued some intensive training, and this (alongside Leo’s click-to-scan functionality) allowed Parke to head straight to site and capture it in full.

“The scanner itself is really intuitive,” explained Parke. “Just having it in an all-in-one package that’s battery-operated makes it so convenient, especially compared to what we had before. “The tracking technology is also next-level. With Leo, we can scan what took two or three hours, in ten minutes. I can’t fault it, it fixes every problem we ever had.”

Artec Studio: “a phenomenal bit of kit”

While USP Maritime have been blown away by their device’s flexible capture capabilities, Parke says it’s what Artec Studio does with this information that “really allows Leo to shine.”

USP Maritime’s initial scan of a 16-meter crane complete with fine surface details.

Parke’s previous 3D scanning programs “would just lock up for days” if loaded with such high quality, Leo-level data. Artec Studio handles multiple scans with ease, allows for rapid alignment, and features all the tools needed to create textured, watertight meshes.

USP Maritime’s old workflow was hampered by cumbersome file sizes, but the team is now able to remove excess frames with Artec Studio’s scan decimation. This makes meshes easier to handle in software like Autodesk Inventor, where they perform further CAD analyses.

“Obviously, we were impressed with the look of the scanner, but the way Artec Studio handles captured information is also incredible,” added Parke. “In the past, I’ve genuinely lost days waiting for a mesh to move or rotate slightly. Artec Studio is a phenomenal bit of kit. What we can produce with it – it’s so far ahead of anything we’ve been able to do before.”

Returning to his first-ever scan as an example, Parke says Artec Leo captured more than enough detail for advanced QA. Even though the decades-old crane had a tricky-to-scan geometry, Leo’s versatility and accuracy meant it could pick up the data needed to assess working condition – from tiny chunks of missing paint to holes drilled in obscured areas.

Artec Leo being used to digitize an engine room with real-time data feedback.

Considering how little time he’d spent with the device, the level of detail captured was remarkable. For this, Parke credits Patrick Thorn, who offered the advice needed to streamline the process, including how to aid alignment with extra data capture and polish rough edges.

The future of maritime MRO?

Creating one-to-one models of nautical equipment with Leo has become key to USP Maritime’s refit workflow. In cases where they need to work around existing pipework, for instance, the team can now scan this and customize brackets or other fixtures so they slot into place.

Parke adds that more recent use cases have seen this principle applied on a grander scale, with Leo even being used to capture 300-kilogram pumps that were “almost impossible to remove” from a ship’s engine. With the vessel in service, the team didn’t have time to experiment.

So, instead of digitizing these colossal components and nothing else, he says USP Maritime 3D scanned the entire area, allowing its team to “come up with a plan remotely.” Doing so has since allowed them to strategize and make repairs quickly when the ship next docked.

A rough engine room scan captured by USP Maritime for future reference.

“In this engine propulsion room, we ended up scanning the whole space, just so that in future, it could be reviewed,” Parke concluded. “Later on, we ended up needing that data. We didn’t even have to do any modeling, we just used it as a representation of the space. It was almost like a video fly-through, but we could actually control and measure from it.”

Moving forwards, Parke believes this approach will become central to USP Maritime MRO, as with any area that may need future repairs, they can now “fire Leo at it just in case,” to ensure they leave no stone unturned.

Since providing initial training, Patrick Thorn has also continued to lend his expertise and support to USP Maritime. Having helped the firm get to grips with the technology, he says “things now seem to be going really well,” with the sale of an additional Artec Studio license and battery pack reflecting how “Artec Leo is now a well-traveled and key tool in the USP team’s workflow and success.”

Scanners behind the story

Try out the world's leading handheld 3D scanners.