Transmission

Scanned with our brand new metrology-grade laser scanner, Artec Point, this transmission is digitally represented in every intricate detail. The 3D model vividly displays the complex assembly of components, including the transmission case, input and output shafts, gear sets, shifting mechanism, differential, and clutch housing. This 3D model is a crystal-clear visual understanding of a transmission's internal workings and how these components interact to transmit power from the engine to the wheels.

The transmission was scanned in just 25 minutes using a thorough process, as the high roughness of the material made it challenging to attach any sort of target. To overcome this, our scanning specialist created a single target cloud from two different positions to effectively align the scans. Optimizing the point cloud was particularly time-consuming for scans with a 0.2mm resolution on such a complex object. For even better performance and reduced processing time, we would advise to scan similarly sized objects at a resolution of no less than 0.4 mm.

Being made of metallic cast, the transmission is highly reflective, which would typically pose a great scanning challenge. However, Artec Point handled it gracefully: a total of six scans were completed, with most of the focus on optimizing the point cloud.

The 3D model offers a 360 degree view of a manual transmission's internal structure. Every intricate detail of each component is clearly visible, allowing for thorough inspection, reverse engineering, or simply understanding of their functions. Not only is the transmission case, the protective outer shell, prominently defined, it is also the input and output shafts that are easily identifiable and ready for exploration.

The intricate 3D replica provides a detailed visualization of the gear sets, the heart of the transmission. The interlocking gears, which are responsible for altering the vehicle's speed and torque, are carefully depicted. The shifting mechanism, including the shifter lever, linkages, and synchronizers, is also clearly illustrated. Even the differential, located at the output shaft, is represented in crispy clean 3D.

This digital twin of a complex mechanical system is a perfect example of what Artec Point can achieve when you need to capture parts for reverse engineering, quality inspection, rapid prototyping, or any other application that requires ultra-detailed scanning. Zoom in to study every gear captured with resolution and accuracy that are truly jaw-dropping.

License

Under Creative Commons license v4, attribution to Artec 3D and a link back to our website is all you need to use this 3D model for free.

Transmission by Artec 3D

Available downloads

Embed 3D model on your website

Similar models

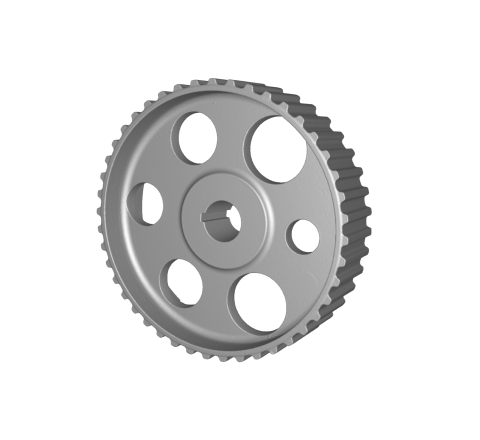

Cam gear • Point

Car rim • Point

Game controller • Spider II

EGR metal connection pipe • Micro II